문서

자주 묻는 질문

코드셋 및 점퍼

<p>Our wiring harness and cable assembly facilities are located in France and India.<br>• In France, we have a dedicated workshop in Thyez to deliver high quality electrical harnesses.<br>• In India, we have over 1500 sq. meter of <a href="https://www.youtube.com/watch?v=5IAiLwO-ICM" target="_blank">cable manufacturing space in India</a> along with 12 assembly lines to design, manufacture, and install harsh environment cable assemblies.<o:p></o:p></p>

<p>We have overmolding machines at Amphenol Socapex AIMS in Pune, India. We are able to manufacture numerous connector configurations tooled up, straight or right angle versions (HE308-38999 series I plugs and receptacles, 38999 series III plugs and receptacles, 2M plugs and receptacles, PT-451 plugs and receptacles……).<br>Our molds are developed and manufactured in-house , if you need a particular configuration, ask us. we can build a new tool within 12 weeks.</p>

<p>Amphenol Socapex and Amphenol AIMS are ISO & EN certified, as well as members of several associations:</p>

<ul>

<li>ISO9001 in Pune, India and Thyez, France</li>

<li>EN9001 Pune, India and Thyez, France</li>

<li>AQAP 2110 in Thyez, France</li>

<li>ISO 14001 in Pune, India and Thyez, France</li>

<li>Member of Industries & local Associations è GICAT , GIFAS, Label Mont-Blanc Excellence Industries, GREEN associations <o:p></o:p></li>

</ul>

<p>Cable testing is performed to check the harness conformity, quality and functionality.</p>

<p>Amphenol Socapex is one of the few cable manufacturers that can boast such a high level of investigation.</p>

<p>We have state-of the-art in-house testing capabilities including:</p>

<p>• Fully automated /programmable electrical testing machines (mt)<br>• Network analyzer for Ethernet and High-speed cable assemblies (fluke)<br>• VNA for Coaxial / RF cable assemblies (network analysze)<br>• Two vector network analyzers (VNA), 20 and 32 GHz, with time domain option</p>

<p>Our <strong>Engineering Technological Laboratory</strong> works in support high level equipment with Signal Integrity Engineers, who know how to characterize harnesses and investigate the causes of malfunctions. <br><br><br> </p>

<article class="align-center">

<img width="652" height="486" alt="automatic electrical tester for cables Cordsets Jumpers" loading="lazy" class="lazyload" data-src="/sites/default/files/styles/optimized/public/media/image/2023-12/automatic_electrical_tester_for_cables.png?itok=ySXLllMO">

</article>

<p><o:p></o:p></p>

<p><em>Automatic Electrical Tester for Cables</em><o:p></o:p><br><br><a href="/en/cable-assembly" target="_blank"><span style="mso-ansi-language:EN-US;" lang="EN-US">Click here to get more details about our different harnesses</span></a><o:p></o:p><br> </p>

<p class="MsoNormal" style="line-height:normal;mso-margin-bottom-alt:auto;mso-margin-top-alt:auto;">We are able to make harnesses that integrate different types of connectors: rectangular connectors, lugs, RF connectors … from other sources than Amphenol, but our focus is on building harnesses with a high content of Amphenol Socapex products.<o:p></o:p></p>

<p>Amphenol Socapex has technological capabilities in overbraiding cable harnesses.<br>Braiding is a good solution to protect harnesses. Braiding technology is a type of shielding built into a cable to allow superior screening (EMI/ EMC) of wire bundles with increased optical coverage, much higher than with separate tubular braids.<br>Braiding cable harnesses are used for sensitive applications such as for missile, marine, and battlefield communications.<br>We have harness braiding machines that operate as a pair: one machine with accessories for metallic bobbins, a second machine with accessories for nomex (textile) bobbins.<o:p></o:p></p>

<p>Yes, we have harness design capabilities. Our dedicated team can help you in the design to define your harness requirement specifications : mockup design support, cable integration…<br>We also provide measurements on model integration of the harness in all environments air, sea, land, space.<o:p></o:p></p>

<p>Our harnesses are manufactured for a wide range of military applications from ground vehicles, deployable communication systems, soldier equipment, navy to UAVs and missiles.<br><o:p></o:p></p>

<p>We have the capabilities to perform the assembly of a diverse range of cables and harnesses based on customer requirements. Our harnesses are manufactured for a wide range of military applications from ground vehicles, deployable communication systems, soldier equipment, navy to UAVs and missiles.<br>Amphenol Socapex is well positioned to support all your cable assembly needs.<br><o:p></o:p></p>

I/O 커넥터

견고한 이더넷, USB 및 디스플레이 커넥터

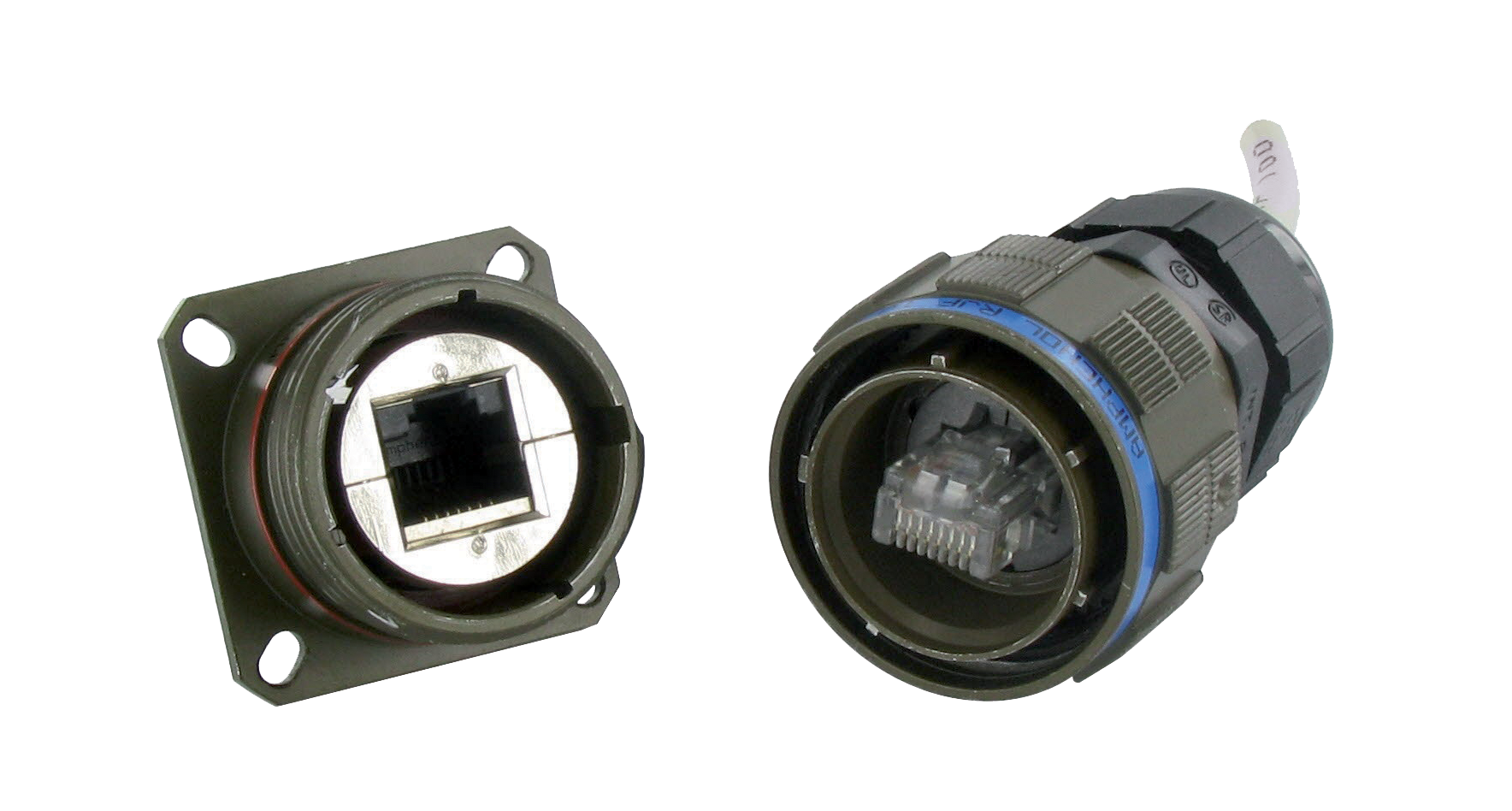

<p>All our solutions are based on the same principle that enables you to <strong>use a standard RJ45 cordset to obtain a ruggedized military cordset</strong>.</p>

<p><u>All cordsets are not military grade for harsh environments</u>, pay carefully attention to your cordset selection. You also choose to purchase <a href="/products/cordsets-jumpers" target="_blank">Amphenol Socapex RJ45 cordsets</a> that are specifically designed for harsh environments.</p>

<p>Our RJ Field Assembly video will show you how easy you can transform a<strong> RJ45 corset into an reinforced military-grade RJ45 Ethernet cordset</strong>.</p>

<p><strong>Any questions regarding our rugged RJ45 connectors?</strong></p>

<ul>

<li>Check out our <a href="https://online.flippingbook.com/view/273380997/61/" target="_blank">RJ Field catalog</a> and/or</li>

<li>Contact our <a href="https://support.amphenol-socapex.com/hc/en-gb/requests/new" target="_blank">Technical Support team</a>.</li>

<li>Watch <a href="https://youtu.be/LJnaIQORFPQ" target="_blank">RJ Field assembly video</a> </li>

</ul>

<p>You just need your 2 hands :) You don't need any special tool or any special cabling skill to transform your RJ45 standard cordset into a ruggedized solution.</p>

<p>Our <a href="https://www.youtube.com/watch?v=TWJxS8eAVTc" target="_blank">RJ Field Assembly video</a> will show you how easy you can transform a RJ45 corset into an reinforced military-grade RJ45 Ethernet cordset.</p>

<p>Any additional questions regarding our Rugged RJ45 connectors? Check our <a href="/products/io-connectors/rugged-ethernet-usb-display-connectors" target="_blank">Rugged Ethernet Connectors product page</a> or contact our <a href="https://support.amphenol-socapex.com/hc/en-gb/requests/new" target="_blank">Technical Support team</a></p>

<p>Depending on your requirements, we have additional accessories available to complete your rugged RJ45 Ethernet solution:</p>

<ul>

<li>Protective caps : used to reinforce and protect your plugs and/or receptacle sealing, we have a large range a protective caps for RJ45 Ethernet connectors. <a href="https://online.flippingbook.com/view/273380997/90/" target="_blank">Check link here</a></li>

<li>Panel gaskets : for square flange receptacle, you need to use a panel gasket. <a href="https://online.flippingbook.com/view/273380997/99/" target="_blank">Check link here</a></li>

<li>Tools : to assembly or disassembly your rugged RJ45 solutions, you might need specific tools which we can provide. <a href="https://online.flippingbook.com/view/273380997/99/" target="_blank">Check link here</a></li>

</ul>

<p>Our <a href="https://www.youtube.com/watch?v=TWJxS8eAVTc" target="_blank">RJ Field Assembly video</a> will show you how easy you can transform a RJ45 corset into an reinforced military-grade RJ45 Ethernet cordset.</p>

<p>Any additional questions regarding our Rugged RJ45 connectors? Check our <a href="/products/io-connectors/rugged-ethernet-usb-display-connectors" target="_blank">Rugged Ethernet Connectors product page</a> or contact our <a href="https://support.amphenol-socapex.com/hc/en-gb/requests/new" target="_blank">Technical Support team</a></p>

<p>All our solution have full shielding continuity based on our product conception : a metallized insert allows full shielding continuity from the cable to the receptacle and the panel.</p>

<p>Reinforced 360° shielding plug kits are also available including a specific backshell. <a href="https://online.flippingbook.com/view/273380997/2/#zoom=true" target="_blank">Click here for more information</a></p>

<p>Yes, all our RJ Field standard solutions are IP68 (1 meter during 1 hour) when plug and receptacle are mated or cap and receptacle are mated.</p>

<p>Our waterproof RJ Field solutions are designed to be used in harsh environments both military and civilian. We offer high-quality, high-durability connectivity products to face these challenges.</p>

<p>Our <a href="https://www.youtube.com/watch?v=TWJxS8eAVTc" target="_blank">RJ Field Assembly video</a> will show you how easy you can transform a RJ45 corset into an reinforced military-grade RJ45 Ethernet cordset.</p>

<p>Any additional questions regarding our Rugged RJ45 connectors? Check our <a href="/products/io-connectors/rugged-ethernet-usb-display-connectors" target="_blank">Rugged Ethernet Connectors product page</a> or contact our <a href="https://support.amphenol-socapex.com/hc/en-gb/requests/new" target="_blank">Technical Support team</a></p>

<p>To increase the sealing of your RJ45 receptacle, you have two different options :</p>

<ul>

<li>You can use a <a href="https://online.flippingbook.com/view/273380997/2/" target="_blank">RJ45 receptacle with a backshell</a></li>

<li>You can use a <a href="https://online.flippingbook.com/view/273380997/2/" target="_blank">RJ45 sealed or hermetic receptacle</a></li>

</ul>

<p>Increasing the sealing of your receptacle will protect your system against ambient influences. Dust and water or moisture are a constant hazard especially in outdoor applications.</p>

<p>Depending on the RJ45 connector you selected, you have different back terminations options that enable you to integrate your receptacle properly into your system:</p>

<ul>

<li><strong>Type 1 </strong>: <strong>Female exit </strong>: you can connect with any standard plug and cordset.</li>

<li><strong>Type1RA</strong> : <strong>Right Angle female exit</strong> : you can connect with any standard plug and cordset.</li>

<li><strong>Type 2 </strong>: <strong>Cordset with standard plug </strong>: you can connect your cordset with your plug to a standard. You can choose your cordset length.</li>

<li><strong>Type 2 OPEN</strong> : <strong>Cordset with an open end</strong> : you can connect your cordset with a plug that you will mount or directly on a PCB. You can choose your cordset length.</li>

<li><strong>PC Tails</strong>: you can directly solder your receptacle on your PCB.</li>

<li><strong>Stand-off</strong> : you can directly solder your receptacle on your PCB and have a mechanical recovery directly on the PCB in order to avoid any damage on PC Tails.</li>

</ul>

관심 있을 만한 다른 제품들

주문할 준비가 되셨나요?

영업 담당자 또는 총판에게 문의하기

RJ45 전술 코드셋

Amphenol Socapex는 열악한 환경에서 사용하도록 설계된 다양한 RJ45 전술 코드셋을 제공합니다. 이러한 이더넷 코드셋은 Cat5e, Cat6, Cat6A 및 Cat7 사양으로 제공되며 1Gb 또는 10Gb의 속도로 안정적인 연결을 제공합니다.

열악한 환경을 견딜 수 있도록 제작된 이 코드셋은 내구성이 뛰어나고 할로겐이 없는 강화 PUR 재킷이 특징입니다. 또한 이중 차폐로 간섭을 방지하고 안정적인 연결을 보장합니다.

이 코드셋은 견고한 구조 외에도 100미터 및 300미터 릴로도 제공되므로 대규모 배포에 이상적입니다. 전장 통신, 지상 차량, 군용 항공 전자 공학, 산업 환경 등 다양한 분야에 적합합니다. 까다로운 환경에서 장비를 연결해야 하거나 열악한 조건에서 안정적인 네트워크 연결이 필요한 경우, Amphenol Socapex RJ45 전술 코드 세트는 필요한 성능과 내구성을 제공합니다. 다양한 사양 중에서 선택하여 특정 응용 분야에 적합한 코드셋을 찾아보세요.