Belangrijkste kenmerken

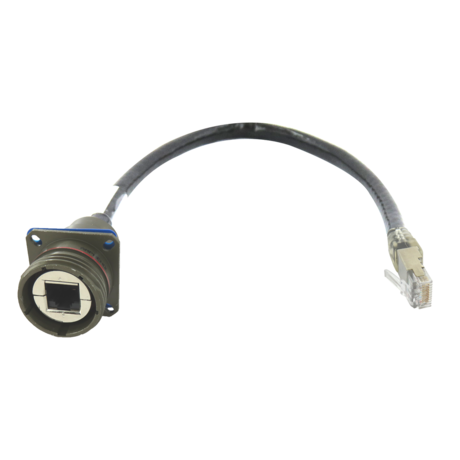

- RJF TV-snoeren met tactische Ethernetkabel

- RJF TV-aansluiting met RJ45 achterkant

Toepassingen

- Communicatie op het slagveld

- Voertuigen aan de grond

- Militaire luchtvaartelektronica

- Industrieel

- 1Gb Cat5e, Cat6

- Versterkt PUR-jasje

- 38999 RJFTV-stekker aan elke kant

- RJF TV - RJ45 Jumper

- Raadpleeg ons voor standaardlengtes

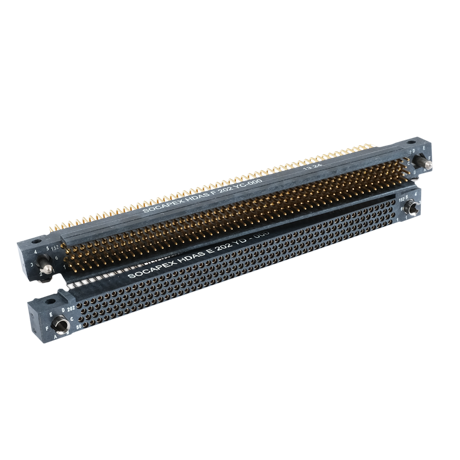

Verwante producten

Amphenol Socapex biedt in de fabriek geteste RJF TV-snoeren en jumpers die klaar zijn om te installeren. Deze kabelsets zijn voorzien van tactische Ethernetkabels en een versterkte PUR mantel voor extra duurzaamheid. De RJF TV plug is gebaseerd op de 38999 connector en is aan beide zijden aanwezig, terwijl de RJF TV receptacle wordt geleverd met een RJ45 achterkant. Deze snoeren en jumpers zijn ideaal voor gebruik in verschillende toepassingen, waaronder communicatie op het slagveld, voertuigen aan de grond, militaire vliegtuigelektronica en industriële omgevingen. Ze ondersteunen 1Gb Cat5e en Cat6 verbindingen, waardoor ze geschikt zijn voor gegevensoverdracht met hoge snelheid. Klanten kunnen bij Amphenol Socapex terecht voor standaardlengtes van deze snoeren en jumpers. Met hun robuuste ontwerp en fabriekstesten bieden deze producten betrouwbare connectiviteitsoplossingen voor veeleisende omgevingen.