MILVA NGVA D38999 Cordsets & Jumpers

MILVA NGVA D38999 Cordsets & Jumpers

Key features

- Ethernet and USB overmolded cables per NGVA STANAG 4754 standard (NATO Generic Vehicle Architecture).

- Amphenol MIL-DTL-38999 Series III plugs, Aluminum

- 3 platings : Black Zinc Nickel, Olive Drab Cadmium, Nickel

- 3 signal possibilities

- Two USB 2.0 ports with standard 9-35 layout

- One 1Gb Cat6 Ethernet port with standard 11-35 layout

- Two 1Gb Cat6 Ethernet ports with standard 13-35 layout

- 3 cordsets terminations Straight plug (more standard), Right angle plug, Free end

- 7 lengths: 0.75 m, 1.0 m, 1.5 m, 2.0 m, 3.0 m, 4.0 m and 5.0 m

- Environment resistance Per MIL-DTL-38999 Series III except operating temperature range: -40degC / +85degC (cables limits)

- IP68 sealed when mated onto receptacle or cap

Applications

- Ground Vehicles Vetronics

- Remote controled Weapon turret

- Military Ethernet & USB networks

- Ethernet Switches

- Battlefield CommunicationsBattlefield Communication

- Grounded vehicles

- Military avionics

Other products you may be interested in

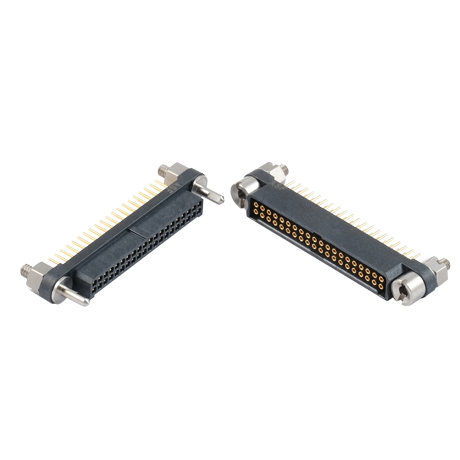

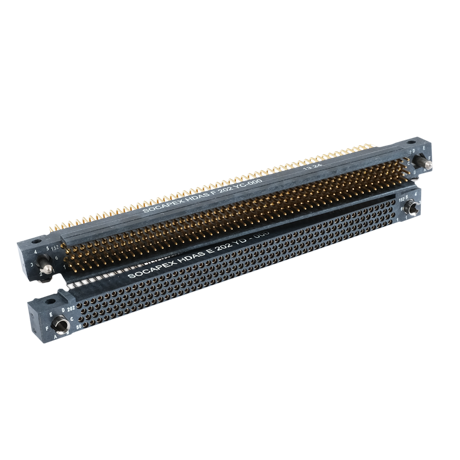

Amphenol Socapex offers high-quality MILVA NGVA D38999 Cordsets and Jumpers that are factory tested and ready to install according to MILVA NVGA standards. These products are designed to provide reliable connectivity in demanding environments, including ground vehicles, remote-controlled weapon turrets, military Ethernet and USB networks, Ethernet switches, battlefield communication, military avionics, and more. One of the key features of these cordsets and jumpers is the use of Ethernet and USB overmolded cables per NGVA STANAG 4754 standard, which is a NATO Generic Vehicle Architecture. The Amphenol MIL-DTL-38999 Series III plugs, available in three platings: Black Zinc Nickel, Olive Drab Cadmium, and Nickel, ensure a secure and stable connection, even in harsh conditions. There are three signal possibilities available: Two USB 2.0 ports with standard 9-35 layout, One 1Gb Cat6 Ethernet port with standard 11-35 layout, and Two 1Gb Cat6 Ethernet ports with standard 13-35 layout.

The cordsets and jumpers are available in three terminations: Straight plug (more standard), right-angle plug, and free end. Seven lengths are also available: 0.75 m, 1.0 m, 1.5 m, 2.0 m, 3.0 m, 4.0 m, and 5.0 m, making it easy for customers to select the appropriate length for their specific needs. Additionally, the cordsets and jumpers are built to withstand harsh environments and are environment-resistant per MIL-DTL-38999 Series III standards, except for the operating temperature range: -40degC / +85degC (cables limits). The IP68 sealing when mated onto receptacle or cap ensures protection against dust, dirt, and moisture.

In summary, the Amphenol Socapex MILVA NGVA D38999 Cordsets and Jumpers are an excellent choice for customers who require reliable connectivity in demanding environments. With their overmolded cables per NGVA STANAG 4754 standard, MIL-DTL-38999 Series III plugs, various signal possibilities, terminations, lengths, and environment resistance, these cordsets and jumpers are built to withstand the toughest conditions and provide excellent performance every time.