MIL-AERO standards

The significance of standards

Military and Aerospace connectors are subject to stringent standards to ensure reliable performance in challenging environments. MIL / AERO industry standards play a pivotal role in assuring customers that what they are investing in is not just a product but a guarantee of excellence.

For Amphenol Socapex, these standards are a testament to their commitment to quality.

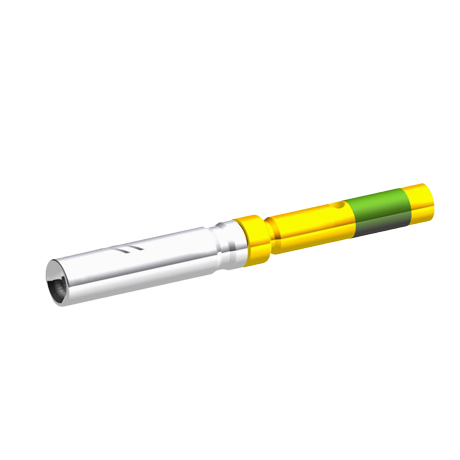

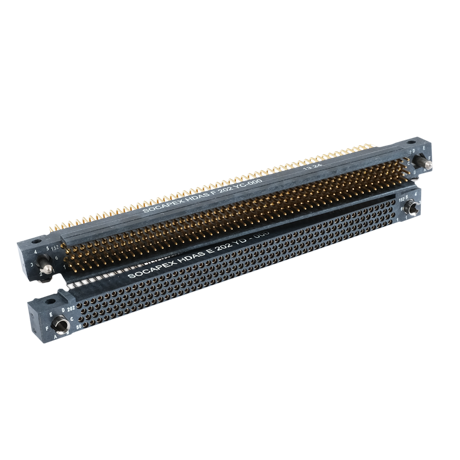

Amphenol Socapex is fully compliant with a comprehensive range of industry standards, including MIL-DTL (26482, 38999, 55302 and 83513), MIL-STD (461,704,810,1275), EN (3155, 3645) , VITA (46 and 66) and HE301 or VG , ensuring the highest level of quality and performance in their connectors and interconnect solutions.

In the ever-evolving landscape of modern industry, standards are the foundation stones upon which reliability, compatibility, and safety are built. Thanks to the mastery of standards, Amphenol Socapex ensure that products don't just meet expectations, but exceed them.

Amphenol Socapex actively participates in committees responsible for creating and maintaining connector standards, including major ones like MIL-DTL-38999 and EN3645.

These standards, which define connector interfaces, dimensions, and performance levels, ensure seamless compatibility and a high level of quality in connectors used across various industries.

Historical Milestones

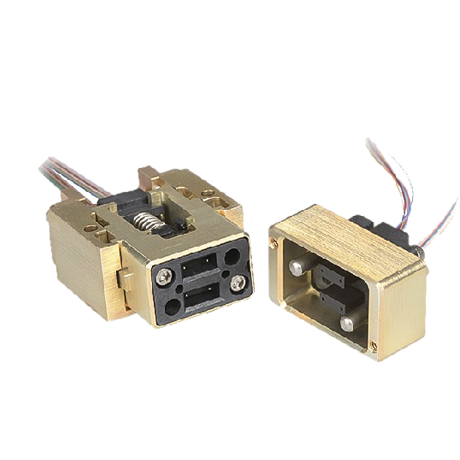

Amphenol Socapex has contributed to the HE308 standard for armored vehicles in the '90s. This standard paved the way for the development of products that continue to be used and sold today, proving the enduring impact of such contributions.

Amphenol Socapex remains at the forefront of industry advancements. Our ongoing efforts focus on digitization and environmental compliance, particularly in meeting REACH/RoHs constraints.

Additionally, we are actively involved in solutions for the electrification of vehicles, ships, and aircraft, ensuring that we stay relevant in an ever-changing market.