MPO Field

Key features

- Uses standard MPO Patchcord

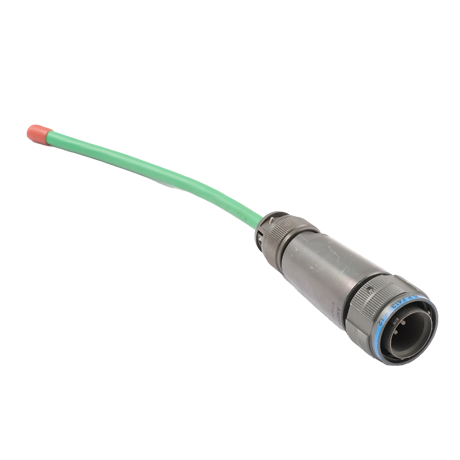

- MPO inside a MIL-DTL 38999 Series III size 13 shell

- Sealed against fluids and dust (IP68)

- Shock, vibration proof

- No cabling operation in field

- Number of channels : 12 or 24 depends on MPO

- Typical insertion loss : 0,5dB Multimode or Singlemode

- Durability : 500 mating/unmating cycles

Applications

- Military communication

- Base Station

- Navy

- Railways

The system allows use of a standard MPO patchcord in a metallic plug, which will protect it from shock, dust and fluids. There is no need for field termination.

This metallic plug is connected into a receptacle, using a Tri Start Thread coupling mechanism (MIL-DTL-38999 Series III type) with anti-decoupling device for high vibrations.

Other products you may be interested in

What is a rugged fiber optic connector and why is it essential for military environments?

A rugged fiber optic connector is designed to withstand harsh conditions such as extreme temperatures, shock, vibration, dust, and moisture. In military environments, reliability is critical for secure communication. Rugged connectors ensure uninterrupted data transmission even in combat zones, naval operations, and field deployments.

How does the Amphenol Socapex MPO Field connector transform an MPO patchcord into a rugged optical connector?

The MPO Field connector allows users to convert a standard MPO patchcord into an environmental connector without field termination. By inserting the patchcord into a metallic plug, it becomes protected against shock, dust, and fluids, making it a rugged optical connector suitable for demanding applications.

Why choose a fiber optic connector with IP68 protection for military and industrial applications?

An IP68-rated fiber optic connector is fully sealed against dust and water immersion. This level of protection is essential for military and industrial environments where connectors may be exposed to rain, mud, or underwater conditions, ensuring reliable performance in all scenarios.

What are the advantages of a rugged fiber optic connector for base stations, navy, and railways?

Rugged fiber optic connectors provide durability and resistance to vibration and shock, which are common in base stations, naval vessels, and railway systems. They guarantee stable connectivity, reduce maintenance costs, and improve system reliability in mission-critical operations.

How does the MPO Field connector’s no-field-termination system save time and reduce errors?

Traditional fiber optic connectors require field termination, which is time-consuming and prone to errors. The MPO Field connector eliminates this step by allowing the use of pre-terminated MPO patchcords, reducing installation time and minimizing the risk of incorrect terminations.

Why is the Tri Start Thread coupling (MIL-DTL-38999 Series III) ideal for high-vibration environments?

The Tri Start Thread coupling mechanism, compliant with MIL-DTL-38999 Series III standards, ensures a secure and vibration-resistant connection. Its anti-decoupling feature prevents accidental disconnection in environments with heavy mechanical stress, such as military vehicles and aircraft.

What is the insertion loss and durability of this rugged optical connector?

The Amphenol Socapex MPO Field connector offers a typical insertion loss of 0.5 dB for both multimode (MM) and single-mode (SM) fibers. It is rated for 500 mating cycles with less than 0.2 dB variation, ensuring long-term performance and reliability.

How many channels does the MPO Field connector support and why is this important?

This connector supports up to 12 channels, making it ideal for high-density fiber optic networks. Multiple channels allow for greater data capacity and efficient space utilization in military communication systems and industrial networks.

How does a fiber optic connector resistant to shock and vibration improve military system reliability?

Shock and vibration can disrupt fiber optic connections, leading to data loss. A rugged fiber optic connector designed to resist these forces ensures continuous communication in military vehicles, ships, and field equipment, where stability is crucial.

Why choose a rugged fiber optic solution over a standard connector in extreme conditions?

Standard connectors are not built for harsh environments. Rugged fiber optic solutions provide superior protection against environmental hazards, mechanical stress, and contamination, making them indispensable for military, aerospace, and industrial applications.