Key features

- Rear accessories in different version: straight, angled, backnuts, cable clamps, EMI, etc

- For EMI version, # termination technologies: braid soldering, clamping, stainless steel band system...

Applications

- Battlefield Communication

- Grounded vehicles

- Military avionics

- Industrial

- For LJT, RNJ, RNJ LP, TV-CTV, SC39 and SJT Connectors

- For MIL-DTL-38999 Series I, II, III, EN3645 and VG96912

- Connectors shell material : Aluminium alloy and Marine bronze

For composite, please consult us

- Finish:

- Olive drab cadmium plating

- Electroless nickel plating

- Green zinc cobalt plating

- Black zinc nickel plating

- For others, please consult us

- Configuration 9 shell sizes per model

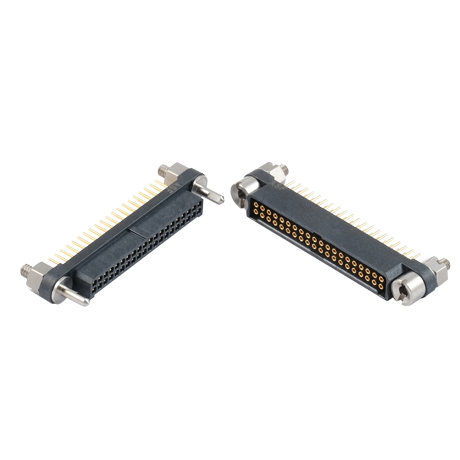

- Straight or right angled versions

- Working temperature :

- From - 65degC to + 175degC with olive drab cadmium plating, green zinc cobalt plating and black zinc nickel plating

- From - 65degC to + 200degC with electroless nickel plating

Other products you may be interested in

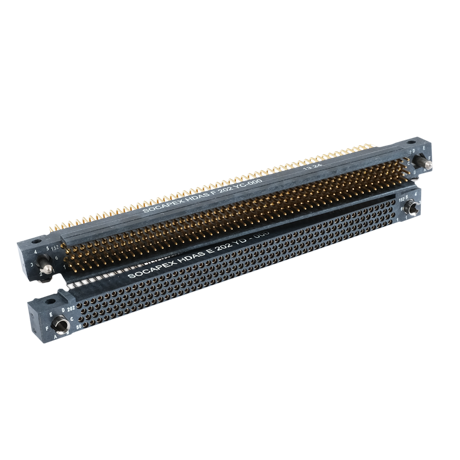

Amphenol Socapex offers a large range of backshells for all their connector series, including the M85049 series and proprietary series. These backshells provide mechanical retention, EMI shielding, or sealing performance to enhance the reliability and performance of cable terminations. The metallic backshells are designed to be robust and reliable, ensuring that cable connections remain secure in demanding environments. They are available in various sizes and configurations, making them suitable for a wide range of applications, including military, aerospace, industrial, and transportation. The unique design of these backshells ensures easy installation and a secure fit, making them a cost-effective solution for enhancing the performance and reliability of connector assemblies.

What is d38999 in line connector?

A D38999 in line connector is a receptacle supplied with no flange for fixing on a panel. It means a cable to cable connexion.

Amphenol’s designation will always begin by TV01 or TVS01.

How do i find the backshell of my connector?

Functions of backshells are:

• Mechanical strength (cable retention)

• Sealing (waterproofness)

• EMI shielding

Amphenol backshell range is made of pieces which can achieve one of this function or a combination of two or three of these functions.

Another solution is to purchase a connector with integrated backshell. This turnkey solution allows cable’s shielding with a metallic band and sealing with an heatshrink boot, with only one part number.